About Us

About Us

Oil Reserve & Demand Analysis

Overview

Crude petroleum is the largest single source of energy in the world, accounting for approximately 35–40% of energy consumed in the world, and is the basic building block for a large number of chemical products consumed globally. In early 2010, global crude petroleum demand was slowly recovering after the first decline in growth since the early 1980's. Demand growth in the US, Japan, and Western Europe will be slow as domestic economies start to improve. In regions such as South and Central America, Africa, Middle East, and Eastern Europe where domestic demand is slowly on the rise, growth will be more robust as markets give way to exports. Asia continues to experience the greatest demand growth and a focus on domestic development. World oil demand is forecast to increase steadily 1-2% through 2011 and rise to 2% for 2012-2014.

"The easy oil is coming to an end," says Alex Munton, a Middle East analyst for the Scottish energy consulting firm Wood Mackenzie.

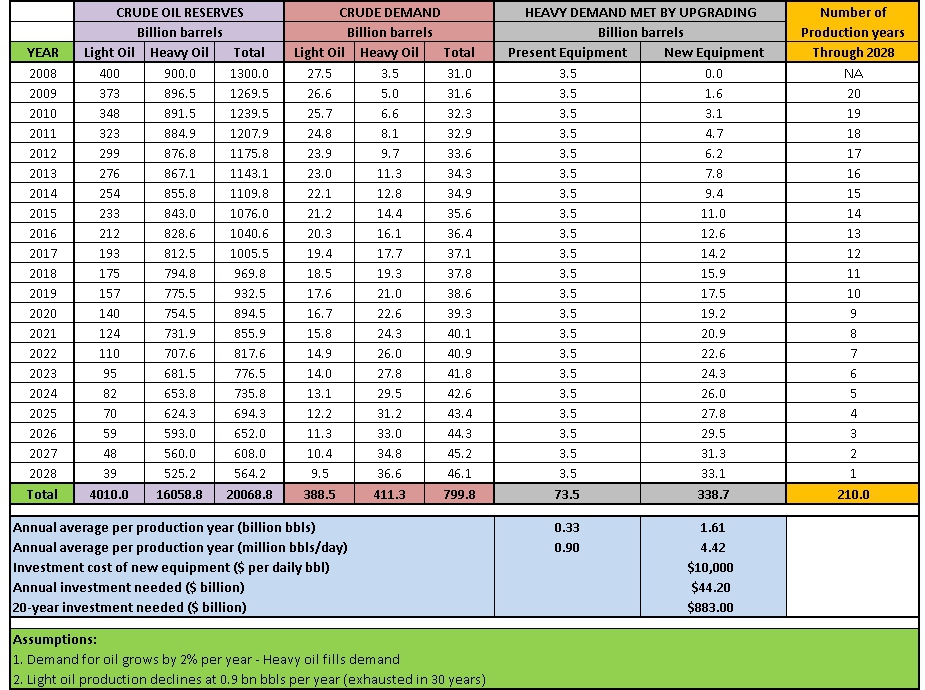

As of January 1, 2010, the estimated world proved reserves of crude petroleum were 1.2 billion barrels. OPEC currently accounts for 71% of total world oil reserves. Saudi Arabia holds the single largest share of the world's petroleum reserves at 19% of the total. On a regional basis, the Middle East accounts for nearly 56% of the world's reserves. North America is second with 15%, and Central and South America is third with 9%, following recent reserves identified in Brazil and Venezuela.

The International Energy Agency (IEA) estimates that 70% of the world’s remaining oil reserves consist of heavy, high sulfur "sour" crude. Oil companies must either seek new sources of lighter, easier to extract and refine, crude oil or find new methodologies to utilize the world’s existing heavy oil reserves. Since the cost for exploration, production and processing continues to climb, the focus should be on the maximum utilization of known reserves by recovering more of the original oil-in-place (“OOIP”) and producing more usable consumer products during refining. The average sulfur content of U.S. Crude oil imports increased from 0.9% in 1985 to 1.4% in 2005, and the slate of imports is expected to continue to sour in coming years. Crude oils are also becoming heavier and more corrosive than they were in the past, largely because fields with higher quality varieties were the first to be developed, and refiners' preference for quality crude oil has led to the depletion of those reserves over the past 100 years reducing the market share of light, sweet crude that remains.

Published reports indicated that at year-end 2007 there were 650 major refineries located around the world. These refineries process a total of 85 million barrels of oil per day. As the sources of premium light-sweet crude oil are depleted, OPEC and other global oil producers will be forced to use increasing amounts of existing heavy-sour crude oil to supply world demand. Not only will additional refining capacity be required to process the increase supply of crude oil, but refineries will need to be designed to process heavier, lower quality crude oil in order to yield the same amount of transportation fuel. For example, premium crude oils yield almost 70% of their volume as light, high-value products (gasoline, diesel, jet fuel, kerosene), whereas heavier crude oils yield only about 50% of their volume as light products. So in order to produce the same amount of refined product from heavy, sour feedstock, a refinery has to have 1.4 times as much capacity (70 divided by 50). There would need to be 182 refineries built (52 more) in order to supply the world with the equivalent amount of transportation fuel in 2017.

As of January 1, 2010, the US had a reserve to production ratio of approximately ten years, while Russia had a reserve production ratio of seventeen years. Opec nations have a reserve ratio of 92 years while oil producing nations in the Middle East has an average of over 100 years.

GHU® TECHNOLOGY DEVELOPMENT HISTORY

Starting in May 1998, Genoil (formerly CE3 Technologies Inc.: Canadian Environmental Equipment and Engineering Technologies Inc.) researched innovative processes for the upgrading of heavy crude oils. Because heavy oil reserves account for the majority of total world oil reserves (including non-conventional oils), Genoil had realized that highly efficient processes were required to economically upgrade these heavy oils to lighter products.

To deliver the heavy oil to the market, heavy oil producers blend it with lighter oils, called condensates or diluents. This requires the implementation of an extensive infrastructure to produce the light oils and to deliver them to the heavy oil field locations. Further, this concentrated demand for light oils for blending could results in shortages and high prices.

Our concept is to upgrade on-site heavy oils to lighter oils meeting pipeline specifications, eliminating the need for blending, increasing the value of the heavy oils, and having a process with economically viable capital and operating costs even for a small-scale field unit of 10,000 bpd. Of equal or greater importance was the development of a hydroconversion upgrader technology for refineries for raising the API gravity of crude oils to refinery specifications and for recovering the refinery’s heavy residuals. Reduction of sulphur, nitrogen and metals was also a similarly critical goal.

Global consumption of fossil fuels is increasing every year and the demand for crude oil is expected to exceed 115 million barrels per day within the next fourteen years. Meanwhile, no new refineries have been built in the United States since 1976 but the race to add refining capacity around the world has already started. Although existing refineries can process most types of crude oil produced today, the yield of transportation fuel is reduced and waste byproducts increased due to the high sulfur and metal composition of the feedstock. For example, it takes nearly three barrels of heavy crude oil to produce the same amount of transportation fuel that is refined from one barrel of light sweet crude. By 2025, the amount of heavy oil produced could be as high as 60% of the total supply based on current trends in new oil discoveries (i.e., limited replacement of depleted oil reserves) and the OPEC basket “blend” of crude oils.

According to USGS statistics, the supply of heavy crude oil to be produced from conventional reservoirs in the North America alone is estimated to be 35 billion barrels using a conservative recovery factor of only 13%. Based on OOIP calculations, an additional 135 billion barrels of oil could be produced from existing US fields using enhanced oil recovery methods. Comparable estimates are available for proven oil basins in South America and the Middle East. The Upstream Optimization Process including advanced waterflood solutions offers oil producers an efficient, cost-effective approach to enhanced oil recovery.

Evaluation of Emerging Technologies for Heavy Oil Upgrading

From May 1998 to January 1999, Genoil researched and evaluated emerging technologies to determine their capabilities for the upgrading of heavy oil. The Genoil initial approach was to study the best parts of other existing technologies, gain an understanding of how each of the different technologies performed. Once it was understood which type of process would achieve the goals set by Genoil and following in-house research, process development and design improvements, Genoil developed a novel field upgrading process that represents a significant advance over current practices.

Genoil evaluated two separate and distinct technologies, previously developed to solve other problems in the oil industry. These technologies were the TaBoRR® process from the Western Research Institute in Laramie, WY, and the CAT process, which is typically used to make diesel fuel. GenOil spent considerable time and effort to test and analyze the technical results and economics of these processes. After a nine-month research and evaluation of these processes, it was concluded that a major shift in technical practices would be required to offer an economical, yet effective, process for heavy oil upgrading.

From a technical basis, it was defined that the CAT process would not be viable for upgrading heavy oils; therefore, bench-scale experiments were not conducted with this process.

Based on the technical merits of the TaBoRR® process (Tank Bottoms Recovery and Remediation), which is a carbon-rejection method (pyrolysis), bench-scale tests were performed using a heavy oil feedstock (12 ºAPI) to determine the potential yields and product quality. A liquid yield of 77.8 wt% was achieved with an average API gravity of 32.3º. Approximately, 13.9 wt% of the feedstock was converted to hydrocarbon gases, and the final 8.3 wt% of the original feed was produced as carbon-laden solids. However, detailed analyses indicated that a liquid yield of only 77.8 wt% limited the chances of an economic success. In addition, the liquid product was not stable (high olefin and diolefins content). Therefore, the TaBoRR® process was a technical success for cracking heavy oil, but had only a slim margin of commercialization, and would be viable only if the liquid yields could be increased.

Genoil GHU™ Process Development

In September 1998, Genoil decided to develop its own heavy oil upgrading process, based on a dual approach of visbreaking and hydroprocessing, and, therefore, by adding hydrogen mass, to obtain an increase in the liquid yields. A hydrogenation process should provide more than 100% of the fresh feed volume, instead of the 75-80% of the carbon rejection processes.

To start the conceptual and preliminary design work on a hydrotreating process to upgrade heavy crude oil, Genoil acquired the Visbreaking technology from the Eadie Group and the “Bullet” technology from the Acquasol Corporation. The Eadie Visbreaking technology was developed through extensive pilot plant work conducted in the early 1990’s at the Alberta Research Council. This Eadie Visbreaking technology was modified and enhanced by Genoil. The bullet technology is a proprietary mixing device, which maximizes the mass transfer between two fluids. Full dispersion of one fluid into the other fluid is achieved (“micro-molecular mixing”) through the bullet, together with the “super-saturation” of the gas into the liquid.

Based on these two technologies, Genoil started developing its own heavy oil upgrading process concept, with the primary goal of improving sufficiently the properties of the heavy oils to meet refinery or pipeline specifications, removing the need for a diluent for transportation.

Key features of the Genoil upgrading are the addition of the hydrogen to the feedstock, and the mixing of the hydrogen with the liquid feed. To confirm this concept, Genoil constructed a laboratory scale prototype vessel together with the appropriate mixing gas/liquid devices. Then, Genoil conducted bench scale tests, at various operating conditions over a period of months, on a Cold Lake Bitumen with an API gravity between 11 and 13º. The main criteria were to achieve high liquid yields and good product stability (no olefins or diolefins). The original Genoil targets were to upgrade the Cold Lake Bitumen from an 11-13º API gravity to an API gravity of 19-20º without a hydrotreating catalyst (hydrovisbreaking), to an API gravity of 22-24º with small amounts of catalyst, and to an API gravity of 28-30º with a hydrotreating reactor (hydroconversion).

These bench scale tests confirmed that “mild” hydrocracking (once-through partial conversion with hydrogen) of the heavy oil feedstock was the way to obtain stable products. Typical visbreaking (without hydrogen) would result in an API increase of only 2-3º and in unstable products. With hydrogen addition, not only the product API could be raised further, but also the product stability was improved. The bench scale tests indicated also that addition of hydrogen limited the condensation of asphaltenes, preventing the formation of coke, allowing higher conversion levels, and resulting in higher product stability together with some desulfurization of the products.

After testing of the proprietary mixing vessel and devices, the next phase of the program was to develop a computer model to test the Genoil concept. Over three months, several simulation studies were conducted to optimize the initial design concept. The simulation results enabled the updating of the process engineering and instrumentation diagram, complete with mass balances and heat balances.

No comments:

Post a Comment